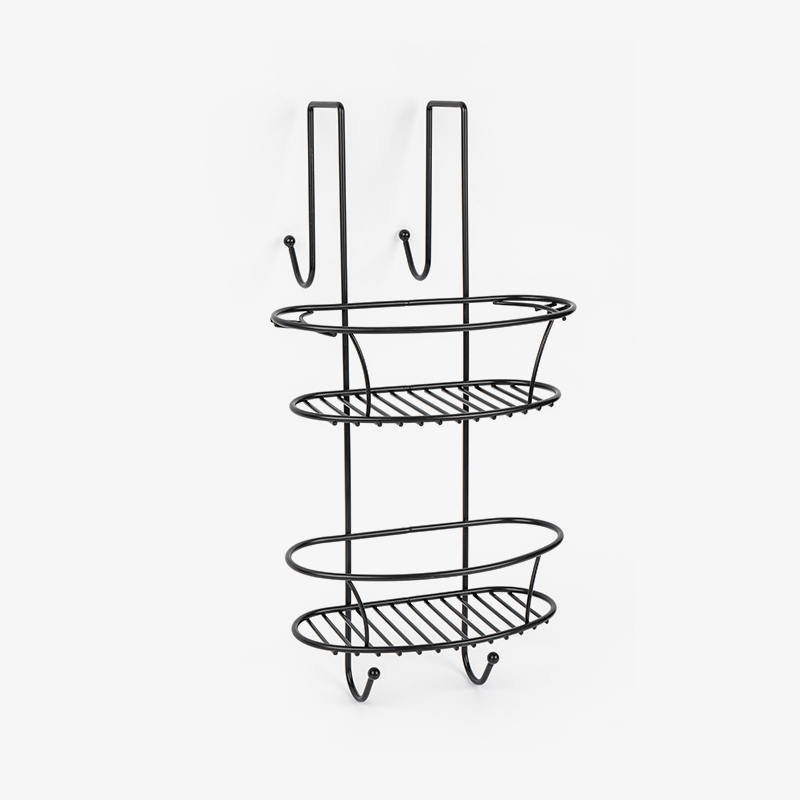

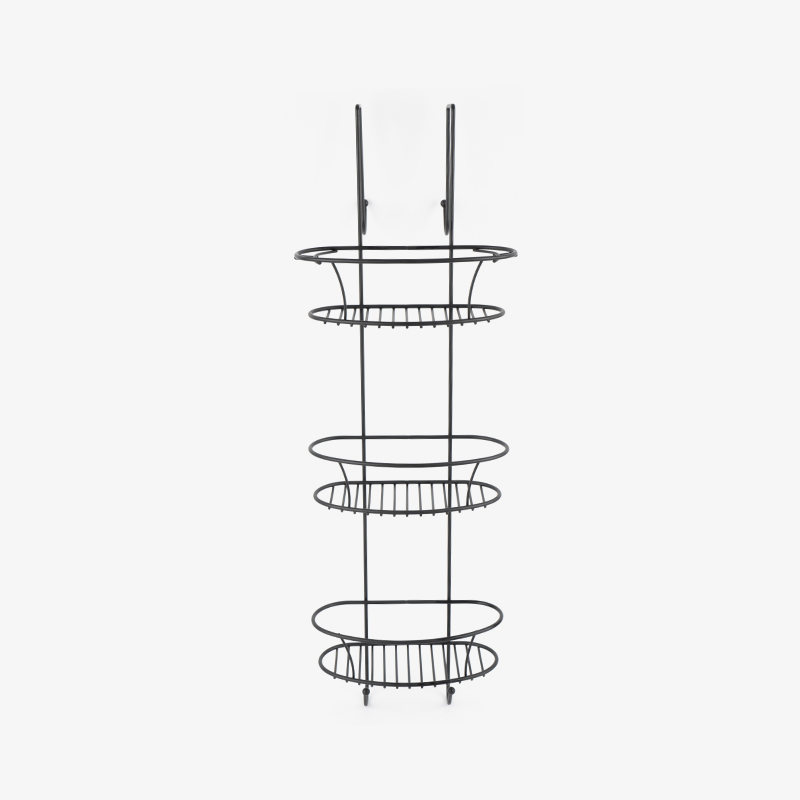

The feasibility of adding hooks or drawers to the home storage rack later depends on the structural reservation of the original frame and the adaptability of the user's transformation technology. For hook-type expansion, nail-free glue can be used to fix metal hanging rods or magnetic accessories. For example, an L-shaped bracket with a movable S-shaped hook can be installed on the edge of the shelf, and the slide hook system can be embedded in the gap between the storage rack columns.

Some modular design frames even have preset standard holes, which can be directly screwed into the screw hooks. Drawer transformation involves deeper structural adjustments. You can choose a custom acrylic tray with a slide rail fixed with nano glue, replace the original shelf with an embedded drawer box, and the depth needs to be controlled within the net depth of the cabinet minus 3-5cm to ensure smooth pulling.

The outer track of the corner deep cabinet can be fixed with carbon steel angle code and cable tie, and the hinge spacing of the drawer tray needs to be accurately measured to avoid interference. If the storage rack is a metal grid structure, the PP material drawer box can be fixed with a cable tie, or the stainless steel thin drawer can be adsorbed by a magnetic component, but it should be noted that the single-layer load should not exceed 5kg to prevent deformation.

When installing hooks, the load-bearing capacity of the wall or frame should be evaluated first. Plastic hooks are prone to aging and falling off. It is recommended to choose 304 stainless steel barbed hooks or copper chrome-plated hooks, fixed with 3M VHB strong tape, and in extreme cases, local drilling and expansion bolts can be used for reinforcement. Innovative solutions include hanging net bags and storage baskets on the top of the storage rack, or using telescopic rods and perforated boards to achieve adjustable expansion of vertical space, but such modifications may affect the overall aesthetics.

Español

Español عربى

عربى