Content

- 1 Key Factors to Consider When Choosing a Metal Storage Organizer

- 2 Design and Configuration Options

- 3 Comparing Metal Storage Organizers with Other Materials

- 4 Surface Finish and Corrosion Protection

- 5 Ergonomics and Accessibility

- 6 Safety and Compliance Considerations

- 7 Maintenance and Longevity

- 8 Cost vs. Long-Term Value

- 9 Frequently Asked Questions (FAQ)

- 10 Choosing the Right Metal Storage Organizer with Confidence

In homes, workshops, offices, garages, and industrial facilities, efficient storage plays a critical role in productivity, safety, and aesthetics. A Metal Storage Organizer has become an increasingly popular solution thanks to its durability, versatility, and ability to handle heavy loads. Unlike plastic or wooden alternatives, metal organizers are engineered to withstand long-term use, harsh environments, and frequent handling.

Selecting the right organizer, however, requires more than simply choosing a size or color. Factors such as material grade, load capacity, intended application, and environmental conditions all influence performance and value. Understanding these elements helps ensure the organizer meets both current and future storage needs.

Key Factors to Consider When Choosing a Metal Storage Organizer

1. Intended Application and Usage Environment

The first step in selecting a Metal Storage Organizer is identifying where and how it will be used. Different environments place different demands on storage systems:

- Home use: Closets, kitchens, laundry rooms, and basements often prioritize appearance, compact design, and moderate load capacity.

- Garage and workshop: These settings require high load-bearing capacity, resistance to oils or chemicals, and flexible configurations.

- Office and commercial spaces: Organization, accessibility, and a clean professional look are essential.

- Industrial and warehouse environments: Heavy-duty steel construction, corrosion resistance, and modular expansion are critical.

Matching the organizer to its environment ensures longevity and optimal performance.

2. Material Type and Construction Quality

Not all metal organizers are built the same. Common materials include:

- Carbon steel: Offers high strength and affordability, commonly used for heavy-duty shelving and racks.

- Stainless steel: Provides excellent corrosion resistance, ideal for humid, medical, or food-related environments.

- Aluminum: Lightweight and rust-resistant, suitable for portable or wall-mounted organizers.

Construction details such as welded joints, reinforced corners, and precision-cut panels significantly affect stability and load capacity. A well-built Metal Storage Organizer minimizes wobbling and deformation even under heavy loads.

3. Load Capacity and Weight Distribution

Understanding load requirements is essential. Overloading shelves can lead to deformation or safety hazards. Manufacturers typically specify:

- Maximum weight per shelf

- Total load capacity

- Recommended weight distribution

For tools, hardware, or bulk materials, selecting an organizer with higher load ratings ensures safety and long-term reliability.

Design and Configuration Options

Fixed vs. Modular Metal Storage Organizer

One of the most important design decisions involves choosing between fixed and modular systems.

- Fixed organizers: Pre-configured and ready to install, offering simplicity and lower cost.

- Modular organizers: Allow customization with adjustable shelves, drawers, bins, and expansion units.

Modular systems provide flexibility as storage needs evolve, making them popular in growing businesses and multi-purpose spaces.

Open Shelving vs. Enclosed Cabinets

The choice between open and enclosed designs impacts accessibility and protection:

- Open shelving: Easy access and visibility, ideal for frequently used items.

- Enclosed cabinets: Protect contents from dust, moisture, and unauthorized access.

Many modern Metal Storage Organizer solutions combine both features to balance convenience and protection.

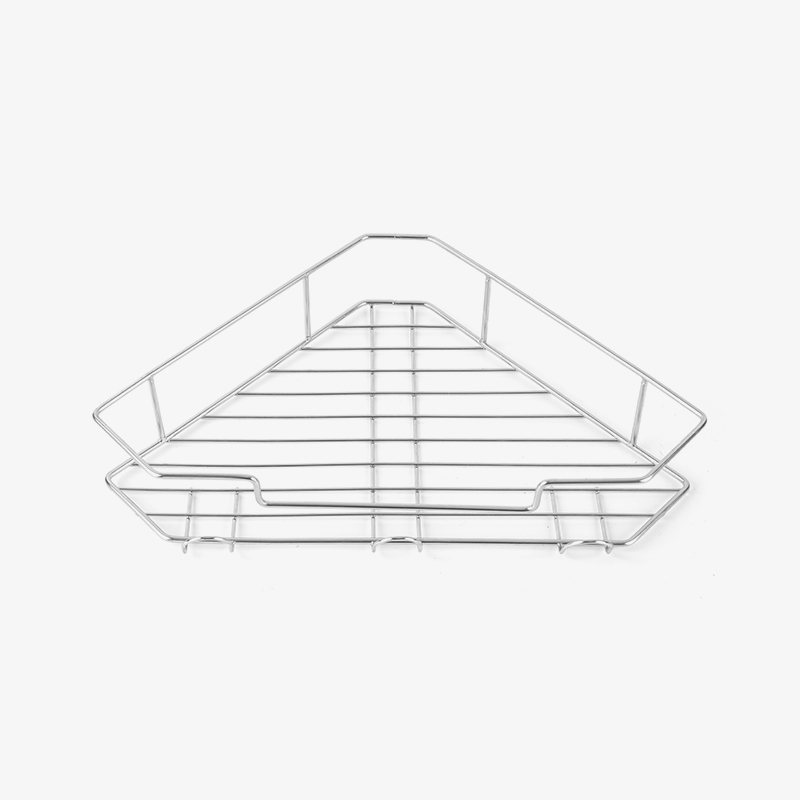

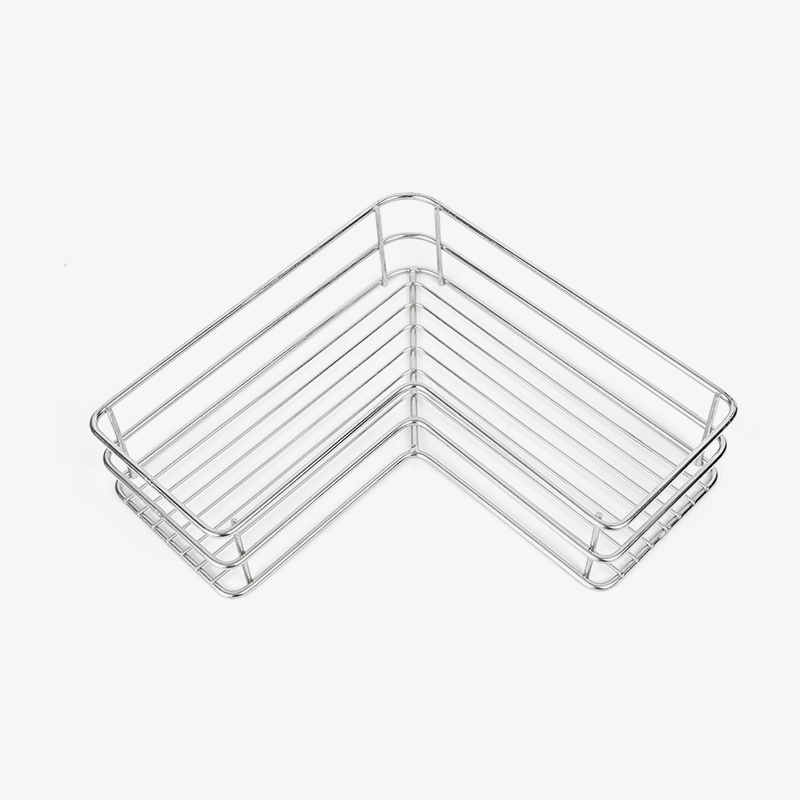

Wall-Mounted vs. Freestanding Systems

Space availability often dictates installation style:

- Wall-mounted organizers: Save floor space and improve organization in compact areas.

- Freestanding units: Offer higher capacity and easy relocation.

Evaluating floor load limits and wall strength is essential before installation.

Comparing Metal Storage Organizers with Other Materials

Metal vs. Plastic Storage Organizers

Plastic organizers are lightweight and affordable, but they lack the durability and load capacity of metal alternatives. A Metal Storage Organizer excels in:

- Heavy-load storage

- Resistance to impact and deformation

- Long-term structural integrity

Plastic solutions may be suitable for light-duty storage, but metal offers superior performance in demanding environments.

Metal vs. Wooden Storage Systems

Wooden organizers provide aesthetic appeal but are sensitive to moisture, pests, and wear. In contrast, metal systems offer:

- Higher resistance to humidity and temperature changes

- Minimal maintenance requirements

- Consistent performance over time

For garages, warehouses, and utility spaces, metal remains the preferred choice.

Surface Finish and Corrosion Protection

Powder Coating

Powder-coated finishes enhance durability and appearance. Benefits include:

- Improved resistance to scratches and corrosion

- Uniform, attractive surface

- Wide range of color options

Galvanized and Stainless Steel Finishes

For outdoor or high-humidity environments, galvanized steel or stainless steel organizers provide superior rust resistance, extending service life even under harsh conditions.

Ergonomics and Accessibility

Shelf Height and Adjustability

Adjustable shelves allow users to store items of varying sizes efficiently. Proper spacing improves accessibility and reduces strain during retrieval.

Drawer Systems and Bins

Integrated drawers and bins enhance organization for small parts and tools. Labeling options further improve efficiency, especially in professional settings.

Safety and Compliance Considerations

Safety features are critical when selecting a Metal Storage Organizer, particularly in workplaces:

- Anti-tip designs or wall anchors

- Rounded edges to reduce injury risk

- Fire-resistant properties in industrial environments

Compliance with local safety standards ensures peace of mind and regulatory adherence.

Maintenance and Longevity

Metal organizers require minimal maintenance compared to other materials. Routine cleaning, periodic inspection for corrosion, and proper weight management help maintain performance for years.

Cost vs. Long-Term Value

While initial costs may be higher, a Metal Storage Organizer often delivers greater long-term value through durability, reduced replacement frequency, and adaptability. Evaluating total cost of ownership provides a clearer picture of overall investment.

Frequently Asked Questions (FAQ)

What size Metal Storage Organizer is best?

The ideal size depends on available space, load requirements, and future expansion plans. Measuring the area and estimating storage volume ensures an optimal fit.

Are metal storage organizers suitable for outdoor use?

Yes, provided they feature corrosion-resistant finishes such as galvanized or stainless steel. Proper placement and maintenance further enhance outdoor performance.

Can a Metal Storage Organizer be customized?

Many modular systems offer customizable shelves, drawers, and accessories to adapt to specific needs.

How much weight can a metal organizer hold?

Load capacity varies by design and material. Heavy-duty models can support several hundred kilograms per shelf when properly installed.

Is installation difficult?

Most organizers include clear instructions. Wall-mounted systems may require professional installation depending on wall structure and load requirements.

Choosing the Right Metal Storage Organizer with Confidence

Evaluating application needs, material quality, design options, and long-term value helps identify the most suitable Metal Storage Organizer. With careful selection, these systems provide efficient organization, enhanced safety, and reliable performance across residential, commercial, and industrial environments.

Español

Español عربى

عربى