As storage efficiency becomes a growing priority in residential, commercial, and industria...

We are committed to providing OEM and ODM services for well-known domestic and foreign brands, and have obtained ISO9001, BSCI, UL, TUV, ROHS certification.

-

-

As homes, workshops, warehouses, and commercial spaces continue to demand smarter organiza...

-

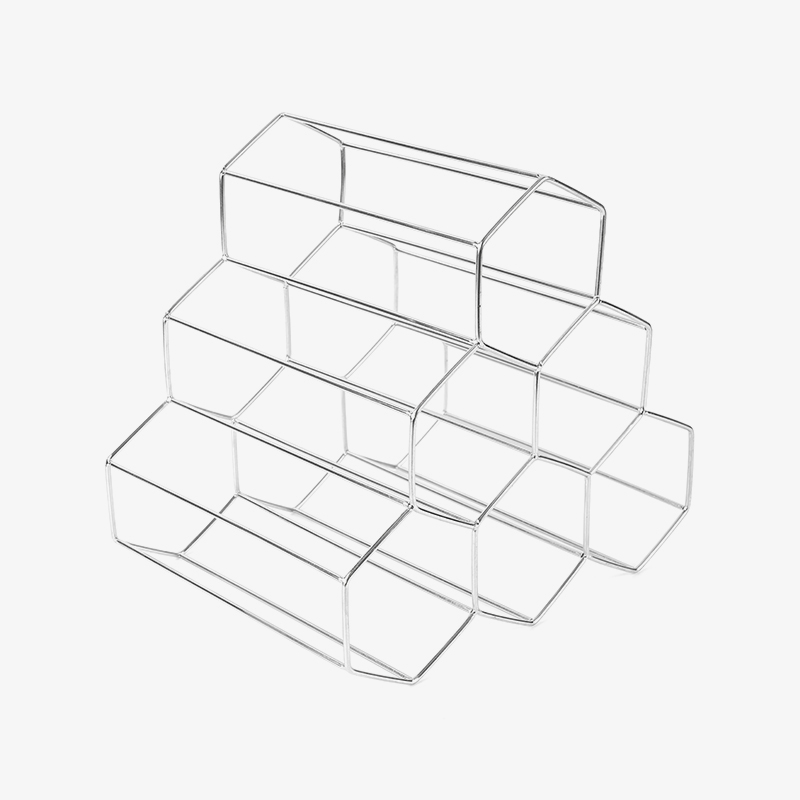

In warehouses, workshops, offices, garages, and even modern homes, a Metal Storage Organiz...

-

In homes, offices, warehouses, retail environments, and industrial facilities, storage sol...

-

In homes, workshops, offices, garages, and industrial facilities, efficient storage plays ...

-

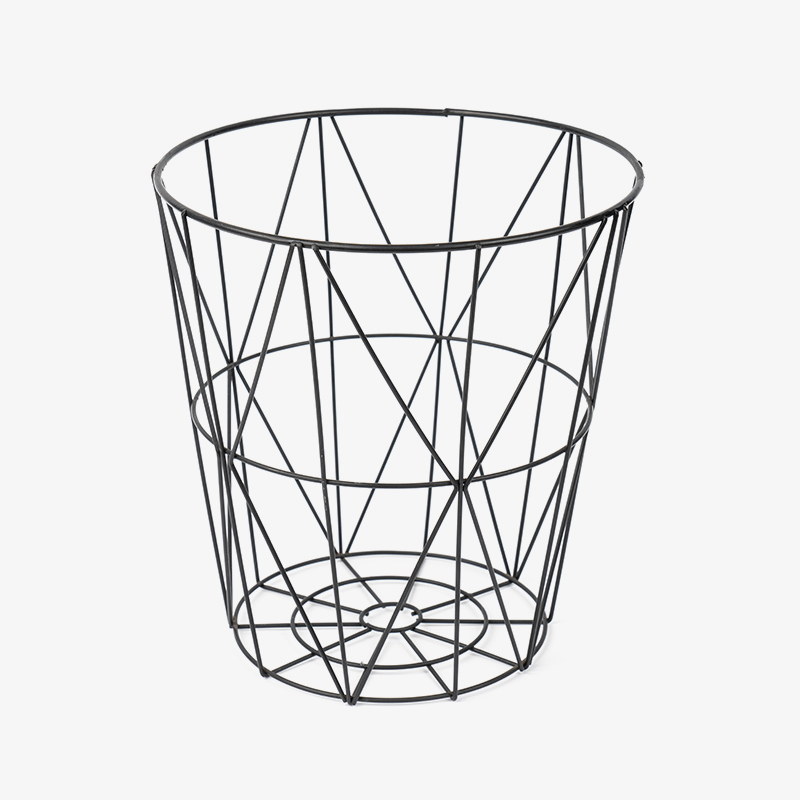

In modern homes and offices, clutter has become a common challenge. Whether it’s stacks of...

As a professional manufacturer with precision manufacturing capabilities across the entire industry chain, we rely on advanced processes such as metal stamping, stretching, laser cutting, welding, and bending. From raw materials to finished products, we strictly control every production link to ensure that we provide you with storage solutions with stable structure and fine workmanship. At the same time, we provide professional OEM/ODM services, and can carry out personalized design and production according to your needs.

We are committed to providing high-quality home storage for modern families, focusing on high-strength home storage rack supplier and home storage basket. Relying on core processes such as stainless steel pipe production, precision stamping, and automated welding, our products strictly follow home safety standards while ensuring load-bearing and durability. Whether it is a standard product or a customized demand, we can provide full-service from design support to mass production, helping you easily create a neat and orderly living space.

We use self-developed precision metal processing technology, and the main frame of the storage rack produced is processed by strict stamping and laser cutting processes to ensure accurate size and stable structure. At the same time, we have a mature surface treatment workshop that can provide anti-rust spraying and other treatments for metal parts, greatly extending the service life of the product.

Thanks to our advanced automated welding equipment and strict quality control system, all metal joints are polished after precision welding to ensure that there are no burrs or cold welds. Our laser cutting process can achieve millimeter-level precision incision processing, and with professional bending and forming technology, all product corners are rounded and smooth. The production line is equipped with professional quality inspection posts to conduct multiple tests on the safety performance of each product to ensure full compliance with international children's home safety standards.

Our engineering team has rich ODM design experience and can develop various modular storage solutions according to customer needs. Through computer-aided design and laser cutting technology, we can quickly realize the proofing and production of various complex structures. Whether it is necessary to add special functional accessories or adjust the overall size specifications, our flexible production line can respond quickly and provide customers with personalized product solutions.

Our independent spraying production line uses an environmentally friendly powder spraying process to provide metal parts with a uniform and firm surface coating. This high-temperature cured spraying treatment is not only beautiful and durable, but also has excellent anti-fouling properties. For plastic parts, we can provide special treatments such as UV protection and anti-aging according to customer needs to ensure that the product will not change color or become brittle after long-term use.

Español

Español عربى

عربى